Bi-line systems, a lesser-known option for tanker truck fall protection, pose significant safety risks, including trip hazards and potential entanglement.

These systems are often unreliable and unused by drivers due to their cumbersome design. Read this blog to understand why bi-line systems fall short in protecting

drivers effectively and what is a much better fall protection solution.

Working at heights on tank trucks is highly dangerous, especially during access and egress. A TRAM Fall Prevention System offers continuous protection

without the need for scheduled preventative maintenance. Read this blog to learn how Standfast TRAM enhances safety for tanker operators.

OEM fall protection systems are often costly, untested, and fail to address critical safety concerns, like ladder transitions. A TRAM system offers

comprehensive, affordable fall prevention for tanker operators. Read this blog to

learn how Standfast TRAM provides reliable protection at a feasible price.

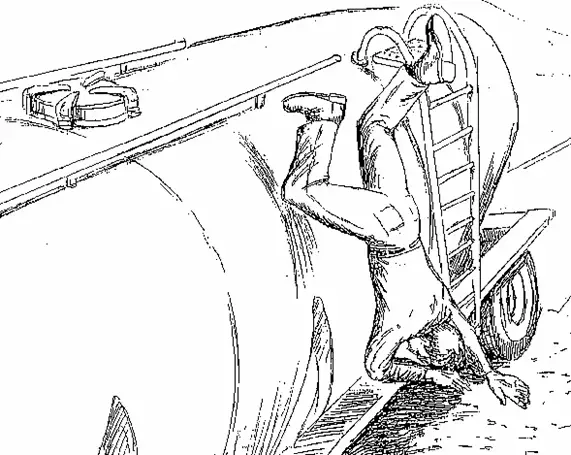

Tank truck drivers face significant risks when climbing atop trailers, with over the overwhelming majority of falls occurring

during access and egress. Proactive height safety measures are essential to prevent severe accidents. Read this blog to explore the

importance of the right fall protection for drivers—that they will use.

Life line systems for tanker trucks are costly and can pose significant safety risks due to their pendulum effect. The TRAM system

offers a safer, more efficient alternative for fall protection. Read this blog to learn why Stanfast TRAM

is the better solution for tanker safety.

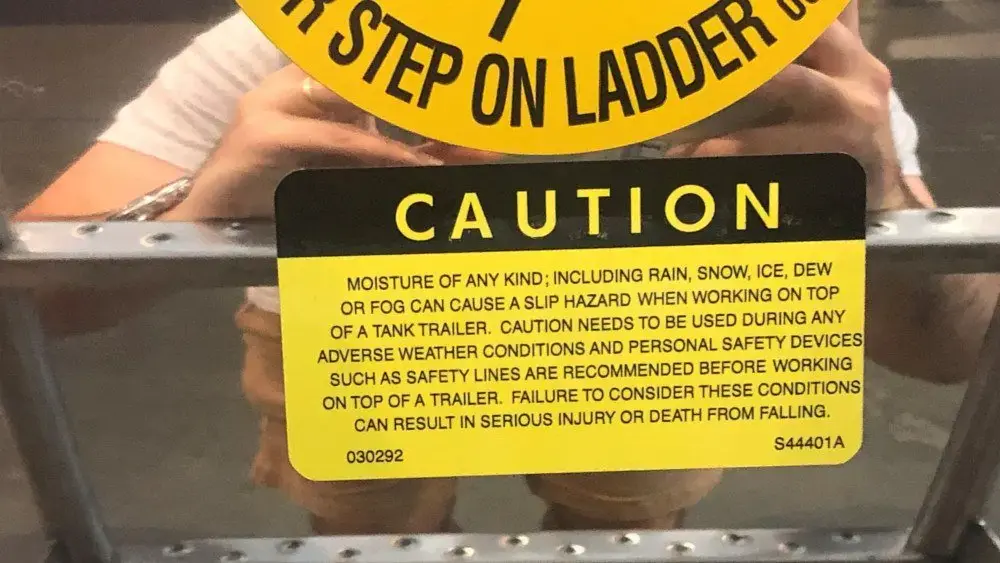

As height safety regulations tighten, handrail systems present numerous challenges, including high costs,

maintenance issues, and limited fall protection. A TRAM system offers a comprehensive solution.

Read this blog to explore how Standfast TRAM addresses these

challenges effectively and overcomes the "hassels with handrails".

The tank truck industry has long required drivers to perform dangerous tasks atop trucks, with most falls occurring during access and egress.

OSHA may soon close loopholes in height safety regulations. Read this blog to learn how the TRAM system, the only

OSHA- and MSHA-certified fall protection on the market, offers a safer solution.

Welcome to the Standfast TRAM blog. We are glad you are here. Bookmark this site and return to find information regarding height safety and fall protection.

Our goal is to provide you with current news and opinion pieces on the status of the this very important topic.

More information can be found on our homepage http://www.sftram.com